Shein increases adoption of eco-friendly denim production

The company produced 380,000 denim pieces using this method last year.

Shein is advancing eco-friendly practices in denim production with the introduction of Cool Transfer Denim Printing, a technology that reduces water and energy consumption.

In 2024, the company produced 380,000 denim pieces using this method, saving over 10,000 metric tons of water— 90% more than in 2023. Since its introduction in 2022, the process has saved nearly 19,500 metric tons of water.

Traditional denim production is resource-intensive, consuming vast amounts of water and energy.

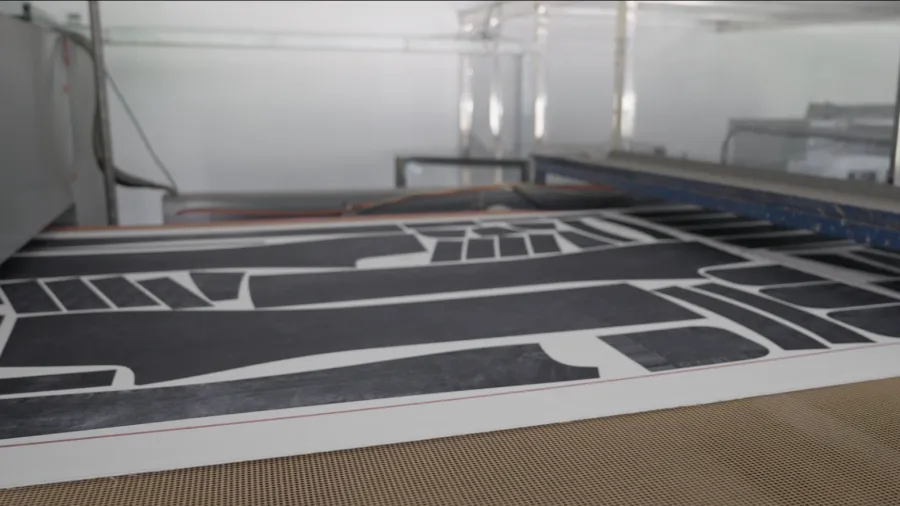

Cool Transfer Denim Printing, developed in partnership with NTX® in 2021, minimises these demands. The method uses a digital printer to transfer reactive ink designs onto denim, replicating effects like fading and whiskering without heavy water use.

The process, verified by Bureau Veritas in 2023, uses 70.5% less water than conventional methods and eliminates exposure to harmful chemicals like chlorine and caustic soda, fostering safer working conditions for factory employees.

This technology complements Shein’s on-demand production model, which matches supply to customer demand to reduce waste. Cool Transfer Denim Printing enables precise, smaller production runs that scale based on real-time feedback, cutting overproduction and excess inventory.

Beyond sustainability, the method enhances creativity, allowing intricate and vibrant designs previously unattainable with traditional techniques.

Advertise

Advertise