SSI Schaefer supplies state-of-the-art picking system to pharmaceutical wholesaler

Long-term success in the pharmaceutical sector calls for the highest transparency and consistent documentation. In order to meet these requirements, Pharmaceutical distribution company Slawex from Lublin, Poland, commissioned warehouse and logistics systems solutions provider SSI Schaefer with the extension and modernisation of their distribution centre in Klaudyn, Poland. The fully automatic picking processes combined with the Schaefer Scan Machine meet pharmaceutical requirements and guidelines, the company revealed.

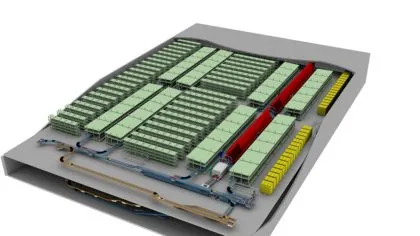

The combination of the fully automated A-Frame picking system and the Schaefer Scan Machine enables efficient single product picking and reading.

The combination of 12 fully automated A-Frame picking systems with the Schaefer Scan Machine facilitates efficient single product picking and reading according to the guidelines of tracking and tracing for pharmaceutical products.

The collaboratively-developed concept is complemented by RF picking, a zomplex bin conveying system, de-stackers and lidding and address insertion machines.

Optimised flow of goods thanks to automation

After dispensing individual products from the automats onto the collecting belt, the products are aligned and read from all six sides by highly-sensitive cameras. Possible reading errors are marked and the affected bins are automatically directed to a check station. Depending on the order structure, the system reads up to 10,000 individual products per hour with batch number, expiry date and serial number – thus enabling a fully automatic, transparent and consistent documentation of pharmaceutical products. Warehouse management and coordinated process control of order handling are achieved with the efficient logistics software WAMAS by SSI Schaefer.

The intralogistics expert implemented the first phase of the system extension during operation in a very short period of time and the scan tunnel will be implemented in the first half of 2018. "The combination of highest efficiency, maximum picking safety with zero-error tolerance and automated digitalisation of all required data was essential for ordering. An innovative system concept is an important component for making our processes prepared for Industry 4.0 and further company growth," summarised Grzegorz Matuszewski, operational director at Slawex.

Brought to you by SSI Schaefer

Advertise

Advertise